**Malting Process:**

– Intake

– Grain received at malt house from farmer

– Cleaning (dressing), drying if needed

– Testing for suitability for malting

– Quality checks: moisture, nitrogen content, foreign matter, fungal growth, germinative capacity

– Water sensitivity assessment

– Drying

– Barley with moisture >13% must be dried

– Circulating heated air (up to 50°C) removes moisture

– Drying done in dedicated grain driers or kiln

– Over-drying damages barley embryos

– Dry barley can be stored up to 18 months

– Cleaning

– Remove foreign matter (straw, chaff, dust, thin corns)

– Magnets remove ferrous metals

– Sieves remove unwanted matter (large/small)

– Aspiration system removes dust and chaff

– De-stoners separate stones from barley

– Storage

– Barley stored in vertical silos made of steel or concrete

– Grain stored to protect from moisture and pests

– Silos store 5,000 to 20,000 tons of barley

– Temperature monitored to prevent insect activity

– Rotation system and fumigation used for maintenance

**Wet Process:**

– Steeping

– Start of malting process

– Grain moisture content increases to 40-45%

– Modern pneumatic malt houses use wet stand and air rest cycles

– Aeration to maximize barley growth

– Draining water starts air rest

– Germination

– Aim is to grow barley grains

– Enzymes modify barley endosperm structure

– Heat produced during germination

– Enzymes needed for starch breakdown during mashing

– Grain bed maintained at 10-16°C

– Kilning

– Reduces grain moisture content

– Stops germination process

– Initial stage keeps air temperatures cool

– Enzymes kept from denaturing during drying

– Final product stable after kilning

**Final Processing:**

– Deculming

– Rootlets of malt (culms) removed after transfer from kiln

– Culms sold or used as animal feed

– Cleaned malt stored in silos for blending

– Blending creates homogenous malt batches

– Malt Cleaning

– Malt cleaned before sale using sieves and aspiration

– Dust, lumps, and stones removed

– Magnets used to eliminate steel debris

– Steel removal prevents damage to mill rollers

**Additional Resources:**

– Dennis Edward Briggs, ‘Malts and Malting,’ 787 p., Chapman & Hall, 1984

– Henry Stopes, ‘Malt and Malting – An Historical Scientific and Practical Treatise,’ 1885

**References:**

– Malt Production on boortmalt.com

– Book ‘Brewing’ by Lewis and Young, Springer, pp.168–171, ISBN9780306472749

– Book ‘Malts and Malting’ by Briggs, Springer, pp.369–389

– The Malting Process on brewconductor.com

– Kilning & Roasting on brewconductor.com

**Malt Culms, Sprouts, Coombs:**

– Information available on fao.org

– Food and Agriculture Organization as source

– Details on malt culms, sprouts, and coombs

– Archived information for reference

This article needs additional citations for verification. (November 2014) |

Malting is the process of steeping, germinating and drying grain to convert it into malt. Germination and sprouting involve a number of enzymes to produce the changes from seed to seedling and the malt producer stops this stage of the process when the required enzymes are optimal. Among other things, the enzymes convert starch to sugars such as maltose, maltotriose and maltodextrines, hence the name malt.

The malt is mainly used for brewing or whisky making, but can also be used to make malt vinegar or malt extract. Various grains are used for malting, most often barley, sorghum, wheat or rye.

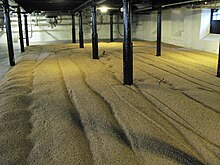

Several types of equipment can be used to produce the malt. Traditional floor malting germinates the grains in a thin layer on a solid floor, and the grain is manually raked and turned to keep the grains loose and aerated. In a modern malt house the process is more automated, and the grain is germinated on a floor that is slotted to allow air to be forced through the grain bed. Large mechanical turners, e.g., Saladin boxes, keep the much thicker bed loose with higher productivity and better energy efficiency.